CORRECT APPLICATION/TECHNIQUES FOR CUT OFF WHEELS

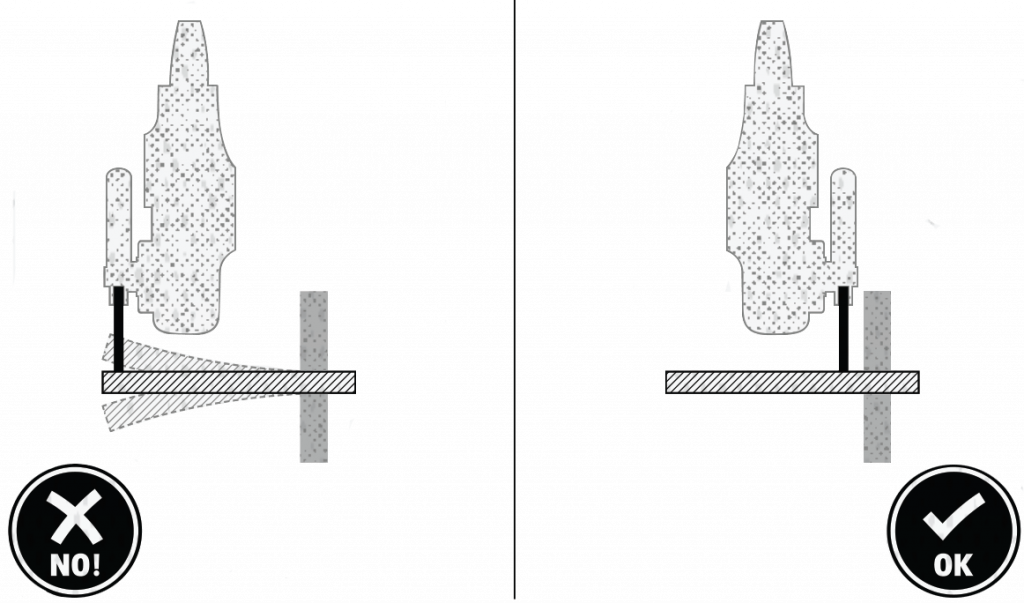

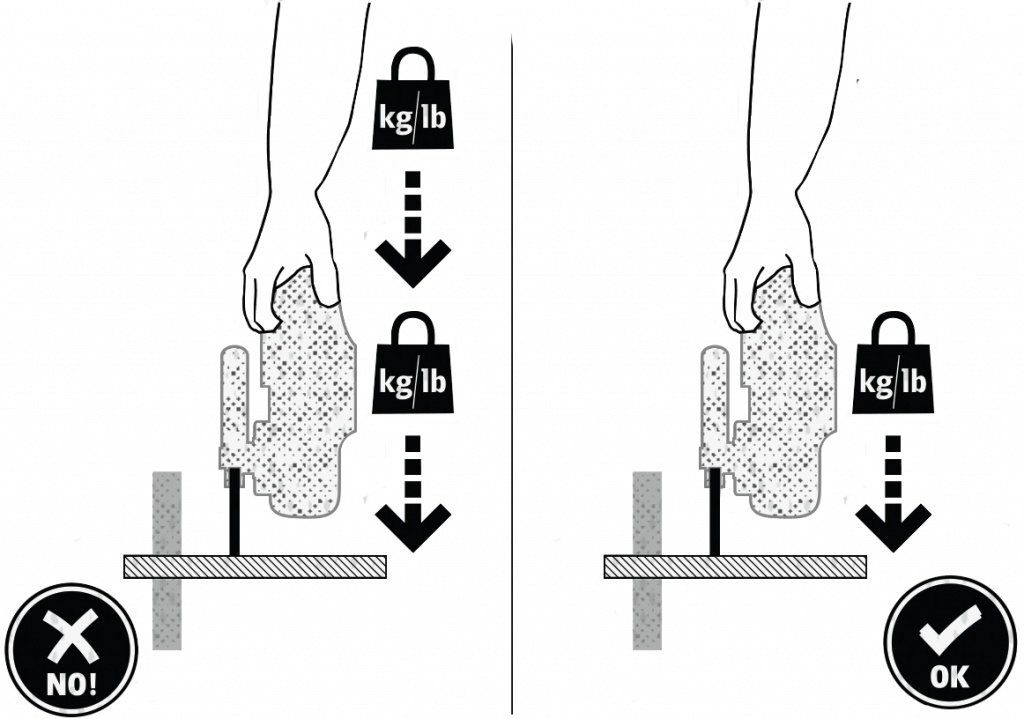

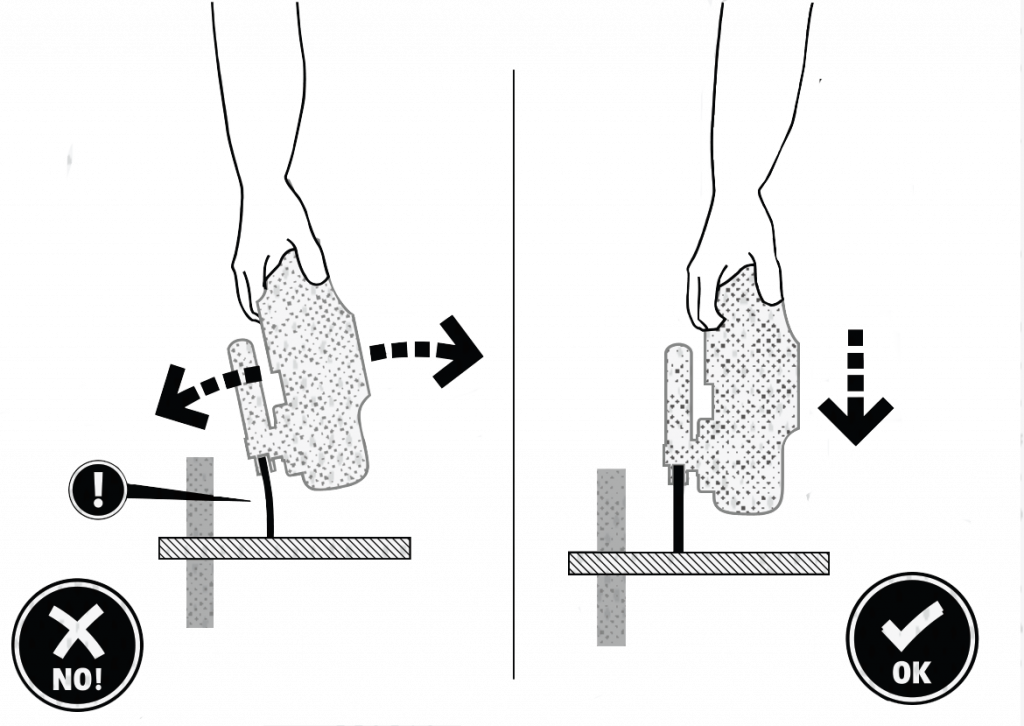

Pressure may only be placed on the cut-off wheel from a radial direction. This is the only way to avoid wobbling, buckling and disc breakage, especially when applying a high level of cutting pressure. The workpiece that is to be cut-off should be properly affixed to the workbench to ensure that the disc does not slide of to the side. In addition, we recommend that the material is axed as close to the cutting site as possible to ensure that it does not vibrate, flflutter or slip to the side.

CORRECT APPLICATION/TECHNIQUES FOR GRINDING WHEELS

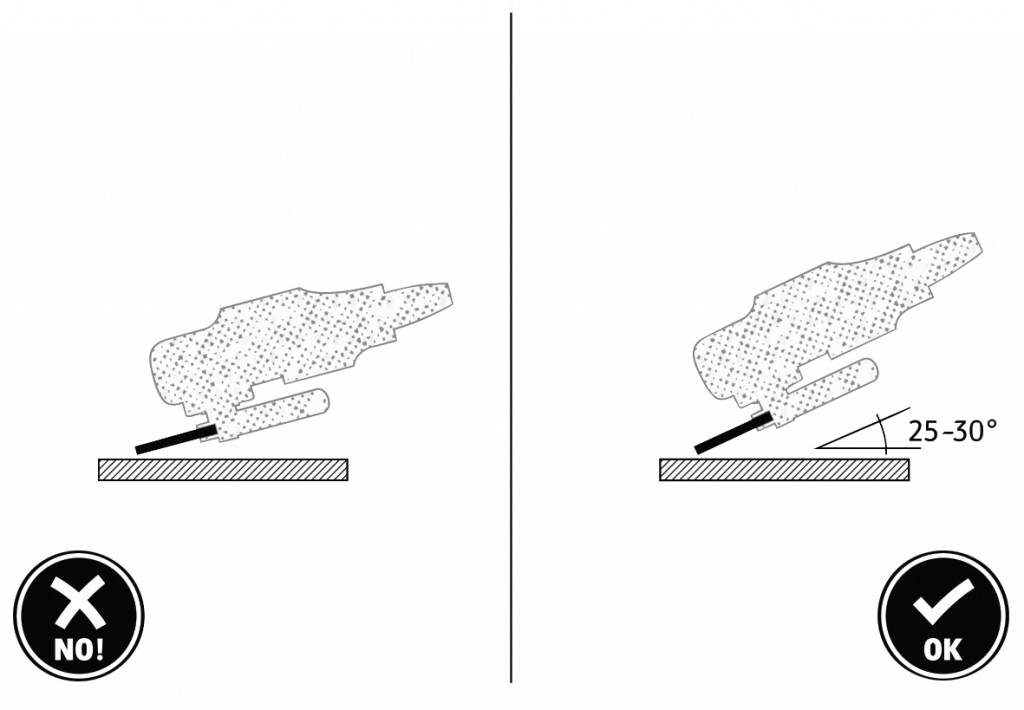

Grinding discs work best at 35 degree angle to the workpiece. This angle provides the best stock removal to disc wear ratio. If possible, always select this angle. When grinding and the angle is below 15 a very thin edge which levels of is formed around the circumference of the disc. Even minimal changes to the angle can result in a situation in which the grinding pressure can no longer be absorbed resulting in the grinding disc slipping to the side. The values of the grit are not used and an imbalance is created that results in having to replace the disc prematurely.